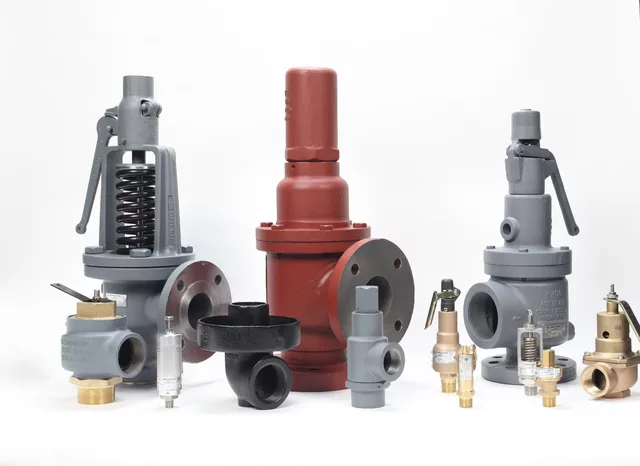

Relief Valve Operation and Guidance

Pressure relief valves (PRVs) are crucial for maintaining safety in systems where pressure can build up to dangerous levels.

These devices automatically release pressure from boilers, pressure vessels, and other systems to prevent accidents and damage.

This page provides an overview of how they work and how to select the correct valve for your application.

What Does a Pressure Relief Valve Do?

Pressure relief valves are commonly found in a wide range of applications. They can be used in compressed air systems, such as pneumatics within industrial automation.

They are also an important component in high-pressure applications such as oil and gas, defense and nuclear, where industrial and process gases are stored and transported at high pressure and need to be regulated down to a safe working pressure before use.

If there is a risk to any individual or process from potential over-pressurisation, a pressure valve should always be used. Furthermore, it is good practice to automatically include them in any standard pneumatic system design.

How Pressure Relief Valves Work

A PRV operates by sensing the pressure inside a vessel. It remains closed under normal conditions, with a spring or other mechanism holding it shut.

When the pressure rises to a predetermined set point, the force overcomes the spring tension, causing the valve to open. This release of excess pressure prevents potential failures.

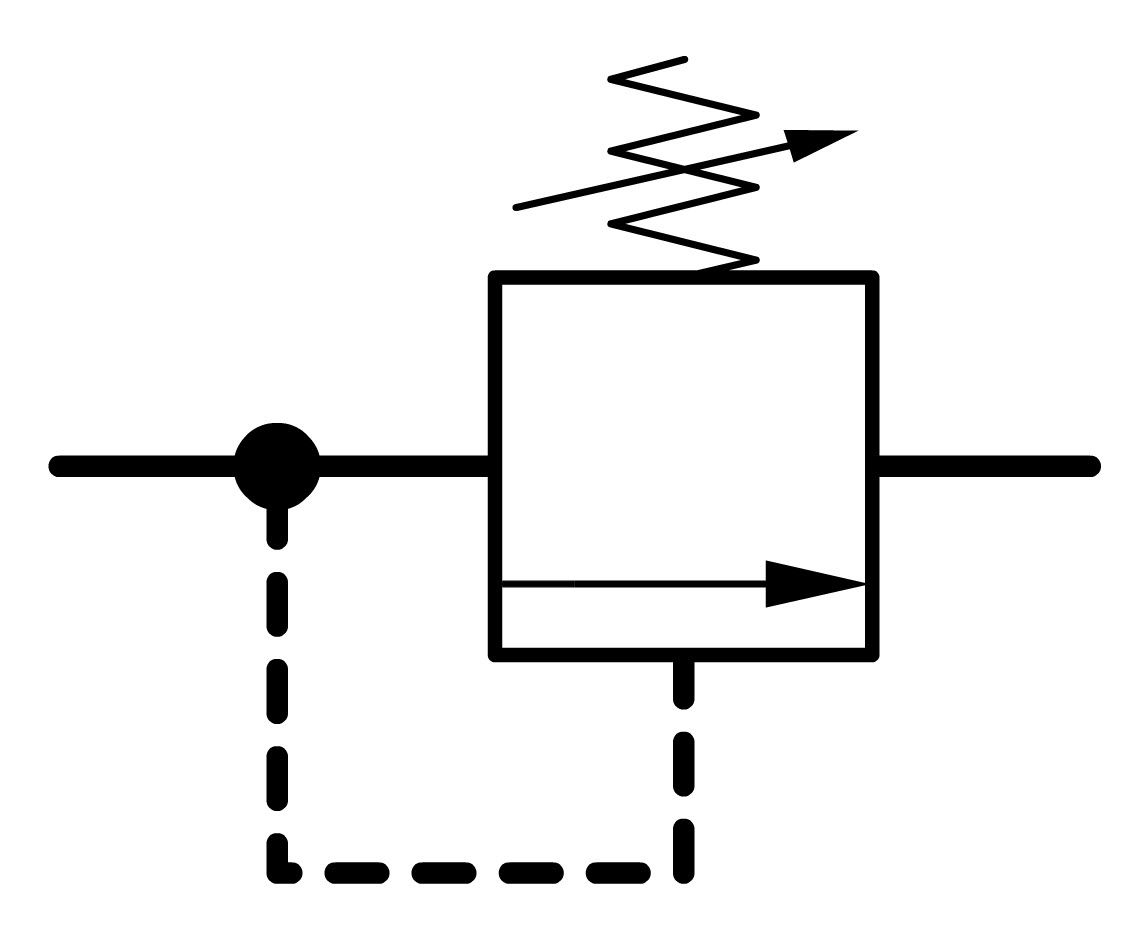

Pressure Relief Valve Symbol

This image shows the pressure relief valve symbol, as it is displayed in a system. This shows a simple, direct-operated PRV valve.

It is worth noting that alternative symbols are sometimes used to denote relief valves used in different systems or electrically-operated PRVs as opposed to hydraulic models.

Choosing the Right Pressure Relief Valve

Selecting the appropriate PRV for a specific application involves careful consideration of several factors:

- Application Requirements: Identify the specific requirements of your system, including the type of fluid being handled (e.g., gas, liquid, steam) and the

operating conditions (e.g., temperature, pressure, flow rate). Different applications may require different types of PRVs, such as spring-loaded, pilot-operated, or balanced bellows valves. Installation requirements such as connections and venting also need to be considered. - Set Pressure: The set pressure of the valve should be chosen based on the system's MAWP, ensuring that it provides adequate protection without

causing unnecessary interruptions. Consult engineering guidelines and industry standards to determine the appropriate set pressure for your application. - Flow Capacity: Ensure the valve can handle the maximum possible flow rate that could occur during overpressure conditions. This is typically expressed as

the valve's relieving capacity, measured in standard cubic feet per minute (SCFM) for gases or pounds per hour (PPH) for liquids. Proper sizing is crucial to

ensure effective pressure relief. - Material Compatibility: Select a valve made from materials compatible with the fluid and environmental conditions. Consider factors such as chemical

compatibility, temperature resistance, and mechanical strength. Common materials for PRVs include stainless steel, brass, and various high-temperature alloys. - Regulatory Compliance: Safety valves can comply with ASME, BS or API standards. In Australia, Safety and Relief valve compliance to AS 1271 has been a minimum requirement for valves fitted to Boiler and other Pressure vessels. ASME is by far a better option as it maintains a higher standard across the board for every certified valve no matter who the manufacturer is. With non compliance to local Codes now a criminal offence in many countries and litigation there after if any industrial issues occur it is very important to know the application and fit the correct valve.

Maintaining Pressure Relief Valves

To keep a relief valve operating within its intended parameters, routine maintenance is required regardless of whether the valve has been installed or operated.

- Regular Inspections: Periodically check for wear, corrosion, or any signs of damage.

- Cleaning: Keep the valve and surrounding area clean to prevent blockages.

- Testing: Perform regular testing to ensure the valve responds correctly to pressure changes.

- Calibration: Ensure the set pressure is accurate by calibrating the valve as per manufacturer guidelines.

- Replacement: Replace valves that show signs of wear or have been in service for an extended period.