Relief Valve Security Mechanisms

When a relief valve is set and certified by Compressor Valve Services, it is validated that the valve adheres to AS1271-2003 in terms of when it opens and closes as well as how it was tested. Any alteration of the valve after certification can potentially put the valve in a state unfit for safe operation so security mechanisms are utilised to ensure that valves and their certificates cannot be tampered with. Compressor Valve Services offers an industry-leading combination of anti-tamper mechanisms which highlights our focus on improving industrial safety.

To verify the validity of a relief valve and its corresponding certification, the below security mechanisms must be checked and found to be current and intact. If a security mechanism is found to be invalid then the valve should not be used until retesting has occurred. For queries related to relief valve certification and validity please contact the valve owner or CVS.

For further information on relief valves refer to our relief valve guidance.

Online Verification

Go straight to the source and remove the risk of tampered certificates. The CVS Certificate portal is an industry-first allowing anyone to retrieve and verify the contents of a certification anywhere, anytime. A QR code linking to the portal is engraved on each valve tag.

Numbered Wire Seals

Individually numbered wire seals match each certificate and valve tag with the wire seal fitting during certification. Look for matching seal numbers across the seal, tag and certificate to verify that the valve's anti-tamper mechanisms are still valid.

Custom Seal Stamps

CVS uses customised seal press dies to emboss our initials on each seal. This is another way to ensure that the lock wire has not been removed.

Lock Wire

Lock wire is used on all points of the valve that allow adjustment or give access to adjustment mechanisms. This control in combination with numbered wire seals and custom seal stamps is a comprehensive guard against physical tampering.

Punched Thread

On valves where lockwire is an insufficient anti-tamper mechanism, the body of the valve is punched such that it locks against the adjustment threads and prohibits changing the set pressure. This method is traditionally used on 1/4" and 1/8" valves.

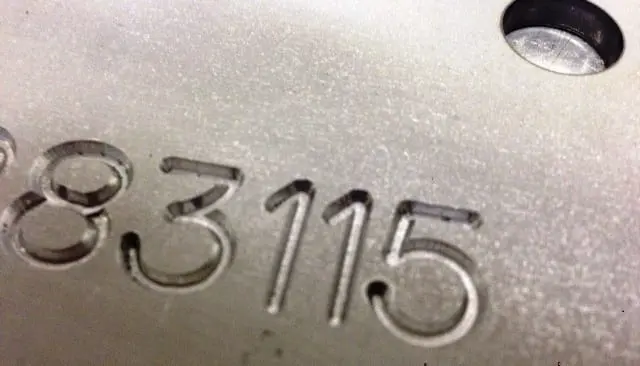

Engraved Body

Each valve will be engraved with a unique serial number to ensure positive identification can be made between the valve, its certificate and the attached tag.